Why Are My Brakes Squeaking? 7 Causes Echo Park Drivers Should Know

Squeaking brakes can transform peaceful drives through Echo Park into sources of embarrassment and concern. That high-pitched squeal when you slow down at a stop sign or pull into your driveway isn't just annoying—it's your vehicle communicating important information about brake system condition. Understanding brake noise causes helps you determine whether you're dealing with a minor nuisance or a serious safety issue requiring immediate attention.

Brake systems represent critical safety components that deserve prompt attention when they signal problems through unusual sounds. While some brake squeaking stems from harmless environmental factors, other causes indicate worn components that compromise stopping power and endanger you, your passengers, and others sharing Los Angeles roads.

This comprehensive guide explores seven common brake noise causes that Echo Park drivers encounter, explaining what creates these sounds, how to identify different types of brake noise, when squeaking indicates serious problems, and how proper brake maintenance prevents noise while ensuring reliable stopping performance. Whether you're hearing occasional squeaks or constant squealing, this information helps you understand what's happening and what actions you should take.

Understanding How Brake Systems Work

Grasping basic brake system operation helps you understand what causes brake noise.

Basic Brake Components

Modern vehicles use disc brake systems on front wheels and often rear wheels as well.

Brake Pads: Friction material that presses against rotors to create stopping force. Pads wear gradually through normal use and eventually require replacement.

Brake Rotors: Metal discs attached to wheels that rotate with tires. Brake pads clamp against rotors to slow and stop vehicles.

Brake Calipers: Hydraulic components that house brake pads and use brake fluid pressure to push pads against rotors.

Brake Fluid: Hydraulic fluid that transfers force from brake pedals to calipers, enabling braking action.

Wear Indicators: Small metal tabs built into brake pads that contact rotors when pad material wears thin, creating deliberate squealing sounds that alert drivers to needed replacement.

How Braking Creates Friction

Understanding the friction process explains why noise sometimes occurs.

Pressure Application: When you press brake pedals, master cylinders pressurize brake fluid throughout the system.

Caliper Activation: Pressurized fluid forces caliper pistons to push brake pads against spinning rotors.

Friction Generation: Contact between pad material and rotor surfaces creates friction that converts kinetic energy (motion) into thermal energy (heat), slowing your vehicle.

Heat Dissipation: Rotors dissipate heat into surrounding air, preventing brake system overheating.

Noise Potential: Any variation in friction material, rotor surface condition, or component alignment can create vibrations that produce audible noise.

Cause #1: Brake Dust Accumulation

One of the most common and least concerning brake noise causes.

What Is Brake Dust?

Brake dust consists of fine particles created during normal braking.

Composition: Brake dust contains tiny particles of brake pad material, rotor material, and environmental contaminants. As brake pads wear against rotors, microscopic particles break away and accumulate on wheels, brake components, and surrounding areas.

Normal Occurrence: All brake systems generate brake dust during regular operation. The amount varies based on driving habits, brake pad material composition, and environmental conditions.

Visible Evidence: You can see brake dust as dark, powdery residue coating wheel surfaces, especially on vehicles with open-spoke wheel designs.

How Brake Dust Causes Squeaking

Accumulated dust interferes with smooth brake operation.

Surface Contamination: Brake dust settling on brake pads and rotors creates uneven surfaces that produce squeaking sounds when brakes engage.

Vibration Creation: Dust particles between pads and rotors cause microscopic vibrations that generate high-frequency sounds we perceive as squeaking.

Temporary Nature: Brake dust squeaking typically occurs intermittently and often disappears after several brake applications that clear accumulated dust.

Environmental Factors: Los Angeles's dry climate allows brake dust to accumulate more readily than in wetter regions where rain naturally washes components.

Identifying Brake Dust Squeaking

Certain characteristics indicate brake dust as the cause.

Intermittent Occurrence: Squeaking happens occasionally rather than constantly, often after vehicles sit unused for periods.

Morning Frequency: First brake applications of the day may squeak more noticeably as overnight dust accumulation gets cleared.

Quick Resolution: Squeaking typically stops after a few brake applications as normal braking clears dust from pad and rotor surfaces.

No Performance Impact: Braking effectiveness remains normal despite squeaking sounds.

Addressing Brake Dust Issues

Simple maintenance reduces brake dust squeaking.

Regular Cleaning: Periodically cleaning wheels and brake components removes accumulated brake dust before it causes noise issues.

Proper Washing: Using appropriate cleaning products and techniques removes brake dust without damaging brake components or wheel finishes.

Professional Inspection: If brake dust accumulation seems excessive, professional inspection ensures brake pads aren't wearing abnormally fast.

Cause #2: Wear Indicators Signaling Pad Replacement

Intentional noise designed to alert you to needed maintenance.

What Are Wear Indicators?

Built-in warning systems that signal brake pad replacement needs.

Design Purpose: Manufacturers install small metal tabs on brake pads specifically to create squealing sounds when pad material wears thin.

Strategic Placement: Wear indicators position precisely so they contact rotors only after pad material wears to minimum safe thickness.

Deliberate Warning: Unlike other brake noises that indicate problems, wear indicator squealing serves as intentional communication that brake service is needed soon.

Safety Feature: This audible warning helps prevent dangerous situations where drivers unknowingly operate vehicles with severely worn brake pads.

How Wear Indicators Sound

Distinctive characteristics help identify wear indicator noise.

High-Pitched Squeal: Wear indicators create loud, high-frequency squealing that's difficult to ignore.

Consistent Occurrence: Unlike intermittent squeaking from brake dust, wear indicator noise occurs every time you apply brakes.

Speed-Related: Squealing typically occurs at lower speeds and may diminish at highway speeds due to wind noise masking it.

Progressive Intensity: Wear indicator squealing often starts quietly and grows louder as pad material continues wearing.

Why Immediate Attention Matters

Ignoring wear indicator warnings creates serious risks.

Safety Compromise: Continuing to drive with worn brake pads reduces stopping power, increasing accident risk.

Rotor Damage: Severely worn pads expose metal backing plates that damage rotors when they make contact, turning affordable pad replacement into expensive rotor replacement.

Complete Brake Failure: Extremely worn pads can fail completely, leaving you with drastically reduced or no braking capability.

Increased Repair Costs: Addressing wear indicator warnings promptly keeps repairs affordable, while ignoring them leads to extensive damage requiring costly repairs.

Proper Response to Wear Indicators

Taking appropriate action protects safety and minimizes costs.

Schedule Service Promptly: When you hear consistent squealing indicating wear indicators, schedule brake inspection and service within days, not weeks.

Avoid Heavy Braking: Until service is completed, drive cautiously and avoid situations requiring hard braking when possible.

Professional Inspection: ASE-certified technicians measure remaining pad material, inspect rotors for damage, and determine complete service needs.

Complete Replacement: Brake pads should be replaced in axle sets (both front or both rear) to maintain balanced braking performance.

Cause #3: Glazed Brake Pads

Heat-related surface changes that reduce friction and create noise.

What Are Glazed Pads?

Hardened brake pad surfaces resulting from excessive heat.

Glazing Process: When brake pads experience extreme heat—often from prolonged hard braking or riding brakes downhill—the friction material's surface can harden and become smooth and shiny, a condition called glazing.

Chemical Changes: Excessive heat causes chemical changes in pad material that alter its friction characteristics and create hard, glass-like surface layers.

Performance Impact: Glazed pads provide reduced friction compared to properly conditioned pads, requiring increased pedal pressure and longer stopping distances.

Common Causes: Frequent hard braking, riding brakes during downhill driving, dragging brakes due to stuck calipers, or using incorrect brake pad materials for driving conditions.

How Glazed Pads Create Noise

Hardened surfaces generate distinctive sounds.

Reduced Friction: The smooth, hard surface of glazed pads doesn't grip rotors as effectively as properly textured pad material, causing pads to slip slightly and create squealing.

Vibration Generation: Inconsistent contact between glazed pad surfaces and rotors produces vibrations that manifest as squeaking or squealing sounds.

Rotor Glazing: Severely glazed pads can transfer glazing to rotor surfaces, compounding friction problems and noise issues.

Persistent Nature: Unlike brake dust squeaking that clears quickly, glazed pad noise continues consistently until the glazing is addressed.

Identifying Glazed Brake Pads

Specific symptoms indicate glazing problems.

Consistent Squealing: Noise occurs regularly during braking rather than intermittently.

Reduced Braking Performance: You notice decreased braking effectiveness, requiring more pedal pressure or longer distances to stop.

Shiny Pad Surfaces: Visual inspection reveals smooth, shiny surfaces on brake pads rather than the slightly rough texture of healthy pads.

Recent Hard Braking: Glazing often develops after extended periods of hard braking, such as mountain driving or emergency stops.

Addressing Glazed Brake Pads

Professional service restores proper brake function.

Pad Inspection: Technicians examine pad surfaces to confirm glazing and assess whether pads can be restored or require replacement.

Surface Restoration: Lightly glazed pads can sometimes be restored by carefully removing the glazed layer, though replacement is often more reliable.

Rotor Service: Rotors must be inspected and resurfaced if they've also developed glazing.

Driving Habit Review: Understanding what caused glazing helps prevent recurrence through improved driving techniques.

Cause #4: Moisture and Environmental Factors

Weather and environmental conditions that create temporary brake noise.

How Moisture Affects Brakes

Water exposure creates temporary noise issues.

Surface Rust: When vehicles sit unused, especially overnight or during rainy periods, thin rust layers form on rotor surfaces. This surface oxidation is normal on exposed metal components.

Morning Squeaking: The first few brake applications after vehicles sit overnight often produce squeaking as brake pads clear surface rust from rotors.

Humidity Effects: Los Angeles's generally dry climate means moisture-related brake noise occurs less frequently than in humid regions, but it still happens during rainy periods or in coastal areas like nearby Santa Monica.

Temporary Nature: Moisture-related squeaking typically disappears within the first few brake applications as normal braking clears rust and dries components.

Environmental Contaminants

Various substances can cause brake noise.

Road Salt: While less common in Los Angeles than snow-belt regions, road treatments and ocean salt in coastal areas can affect brake components.

Dirt and Debris: Dust, sand, and other particles accumulating on brake components create noise until cleared by normal braking.

Oil and Grease: Contamination from leaking fluids or improper lubrication can cause squeaking and reduce braking effectiveness.

Pollen and Organic Matter: During high-pollen seasons, organic materials can accumulate on brake components and create temporary noise.

Distinguishing Environmental Noise

Certain patterns indicate environmental causes.

Timing Patterns: Noise occurring primarily after vehicles sit unused suggests environmental factors rather than mechanical problems.

Quick Resolution: Environmental noise typically disappears within minutes of driving as normal braking clears contaminants.

Weather Correlation: Increased squeaking during or after rain indicates moisture-related causes.

No Performance Change: Braking effectiveness remains normal despite squeaking sounds.

Managing Environmental Brake Noise

Simple approaches address environmental factors.

Regular Driving: Vehicles driven daily experience less environmental brake noise than those sitting unused for extended periods.

Covered Parking: Garaging vehicles or using covered parking reduces moisture exposure and environmental contamination.

Post-Rain Driving: Gentle brake applications after rain help clear moisture without aggressive braking.

Professional Cleaning: If environmental contamination seems excessive, professional brake cleaning removes accumulated materials.

Cause #5: Brake Hardware Issues

Problems with components that support and guide brake operation.

Understanding Brake Hardware

Various components beyond pads and rotors affect brake operation.

Anti-Rattle Clips: Spring clips that hold brake pads securely in calipers and prevent vibration and noise.

Shims: Thin metal or rubber layers between brake pads and caliper pistons that dampen vibrations and reduce noise.

Slide Pins: Pins that allow caliper brackets to move smoothly, ensuring even pad contact with rotors.

Hardware Kits: Complete sets of clips, shims, and other small components that support proper brake operation.

How Hardware Problems Create Noise

Worn or missing hardware allows unwanted movement and vibration.

Loose Pads: When anti-rattle clips wear out or break, brake pads can move within calipers, creating rattling or squeaking sounds.

Missing Shims: Brake pads installed without proper shims lack vibration dampening, resulting in increased noise.

Corroded Slide Pins: Rusty or seized slide pins prevent smooth caliper movement, causing uneven pad contact that generates noise.

Worn Springs: Degraded return springs allow components to move improperly, creating various noises.

Identifying Hardware-Related Noise

Specific characteristics suggest hardware problems.

Rattling Sounds: Loose hardware often creates rattling rather than pure squeaking, especially over bumps.

Inconsistent Noise: Hardware issues may produce noise that varies with road conditions and vehicle movement, not just braking.

Recent Service: If squeaking began shortly after brake service, missing or improperly installed hardware may be responsible.

Visual Evidence: Inspection may reveal missing clips, damaged shims, or corroded components.

Proper Hardware Maintenance

Quality service includes complete hardware attention.

Replacement During Service: Professional brake service includes replacing all hardware components, not just pads.

Quality Parts: Using manufacturer-specified or equivalent-quality hardware ensures proper fit and function.

Proper Installation: Correct hardware installation requires knowledge and attention to detail.

Lubrication: Appropriate lubrication of slide pins and contact points prevents corrosion and ensures smooth operation.

Cause #6: Rotor Surface Problems

Issues with brake rotor condition that generate noise.

Common Rotor Problems

Various rotor conditions cause brake noise.

Uneven Wear: Rotors that wear unevenly develop high and low spots that create pulsating and squeaking during braking.

Scoring and Grooving: Deep scratches or grooves in rotor surfaces result from severely worn brake pads or debris caught between pads and rotors.

Warping: Heat-related distortion causes rotors to develop uneven surfaces that produce vibration and noise.

Rust and Corrosion: Surface rust creates temporary noise, while deeper corrosion damages rotor integrity.

Thickness Variation: Rotors that wear to different thicknesses around their circumference create pulsating and noise.

How Rotor Issues Cause Noise

Surface irregularities disrupt smooth brake operation.

Inconsistent Contact: Uneven rotor surfaces prevent consistent pad contact, creating vibrations that manifest as squeaking or squealing.

Pad Vibration: As pads encounter high and low spots on rotors, they vibrate at frequencies we hear as brake noise.

Harmonic Resonance: Certain rotor conditions create vibrations at frequencies that amplify through brake components, producing loud squealing.

Progressive Worsening: Rotor problems typically worsen over time as continued use exacerbates existing damage.

Identifying Rotor-Related Noise

Specific symptoms indicate rotor problems.

Pulsating Pedal: Brake pedal pulsation accompanying noise strongly suggests rotor problems.

Speed-Related Changes: Noise intensity varying with vehicle speed indicates rotor surface issues.

Steering Wheel Vibration: Vibration felt through steering wheels during braking often relates to front rotor problems.

Visual Damage: Inspection reveals visible scoring, grooving, or discoloration on rotor surfaces.

Addressing Rotor Problems

Professional service restores proper rotor condition.

Rotor Measurement: Technicians measure rotor thickness to ensure adequate material remains for service.

Resurfacing: Rotors with sufficient thickness and minor surface problems can be resurfaced to restore smooth surfaces.

Replacement: Severely worn, warped, or damaged rotors require replacement.

Matched Service: When replacing brake pads, rotors should be resurfaced or replaced to ensure proper pad break-in and optimal performance.

Cause #7: Incorrect or Low-Quality Brake Components

Parts quality and compatibility significantly affect brake noise.

How Component Quality Matters

Not all brake parts perform equally.

Material Composition: Brake pad friction material varies significantly between manufacturers and quality levels. Some formulations are inherently noisier than others.

Manufacturing Standards: Quality manufacturers maintain tight tolerances and consistent material composition, while low-quality parts vary significantly.

Design Specifications: Brake components designed for specific vehicles ensure proper fit, function, and quiet operation.

Cost vs. Quality: While premium parts cost more initially, they typically provide quieter operation, better performance, and longer service life.

Common Problems with Incorrect Parts

Using wrong or low-quality components creates issues.

Excessive Noise: Some aftermarket brake pads, particularly very inexpensive options, produce significantly more noise than quality parts.

Poor Performance: Low-quality brake components may provide adequate stopping power initially but degrade quickly.

Premature Wear: Inferior materials wear faster, requiring more frequent replacement.

Compatibility Issues: Parts not designed for specific vehicles may not fit properly, causing noise and performance problems.

Identifying Component-Related Noise

Certain patterns suggest parts quality issues.

Noise After Service: If squeaking begins immediately after brake service using new parts, component quality or compatibility may be responsible.

Consistent Squealing: Low-quality pads often produce constant squealing regardless of conditions.

Rapid Wear: If brake pads wear unusually quickly, quality issues are likely.

Multiple Complaints: If you hear about others experiencing similar noise with the same parts, quality problems are probable.

Ensuring Quality Brake Components

Proper parts selection prevents noise and ensures performance.

OEM or Equivalent: Using original equipment manufacturer (OEM) parts or equivalent-quality aftermarket components ensures proper fit and performance.

Reputable Brands: Established brake component manufacturers with strong reputations typically produce quality products.

Professional Recommendations: ASE-certified technicians understand which brake components provide optimal performance and value for specific vehicles.

Warranty Coverage: Quality brake components come with warranties that protect against defects and premature failure.

When Brake Squeaking Indicates Serious Problems

Understanding which brake noises require immediate attention protects safety.

Warning Signs Requiring Urgent Service

Certain symptoms indicate potentially dangerous brake problems.

Grinding Sounds: Deep grinding noises indicate metal-on-metal contact, meaning brake pads have worn completely through and backing plates are damaging rotors. This requires immediate service.

Constant Squealing: Persistent, loud squealing during all braking suggests wear indicators or severely worn pads requiring prompt attention.

Reduced Braking Performance: Any decrease in braking effectiveness, regardless of noise, demands immediate professional inspection.

Brake Pedal Changes: Pedals that feel soft, sink toward floors, or require excessive pressure indicate serious brake system problems.

Pulling to One Side: Vehicles pulling left or right during braking suggest uneven brake wear or caliper problems.

Vibration: Significant vibration through brake pedals or steering wheels indicates rotor problems or other serious issues.

Risks of Ignoring Brake Problems

Delaying brake service creates serious consequences.

Safety Compromise: Worn or damaged brakes increase stopping distances and reduce your ability to avoid accidents.

Progressive Damage: Brake problems worsen over time, turning simple repairs into extensive, expensive service needs.

Complete Brake Failure: Severely neglected brakes can fail completely, leaving you unable to stop safely.

Liability Issues: Operating vehicles with known brake problems creates legal liability if accidents occur.

Professional Brake Inspection and Service

Expert service ensures safe, quiet brake operation.

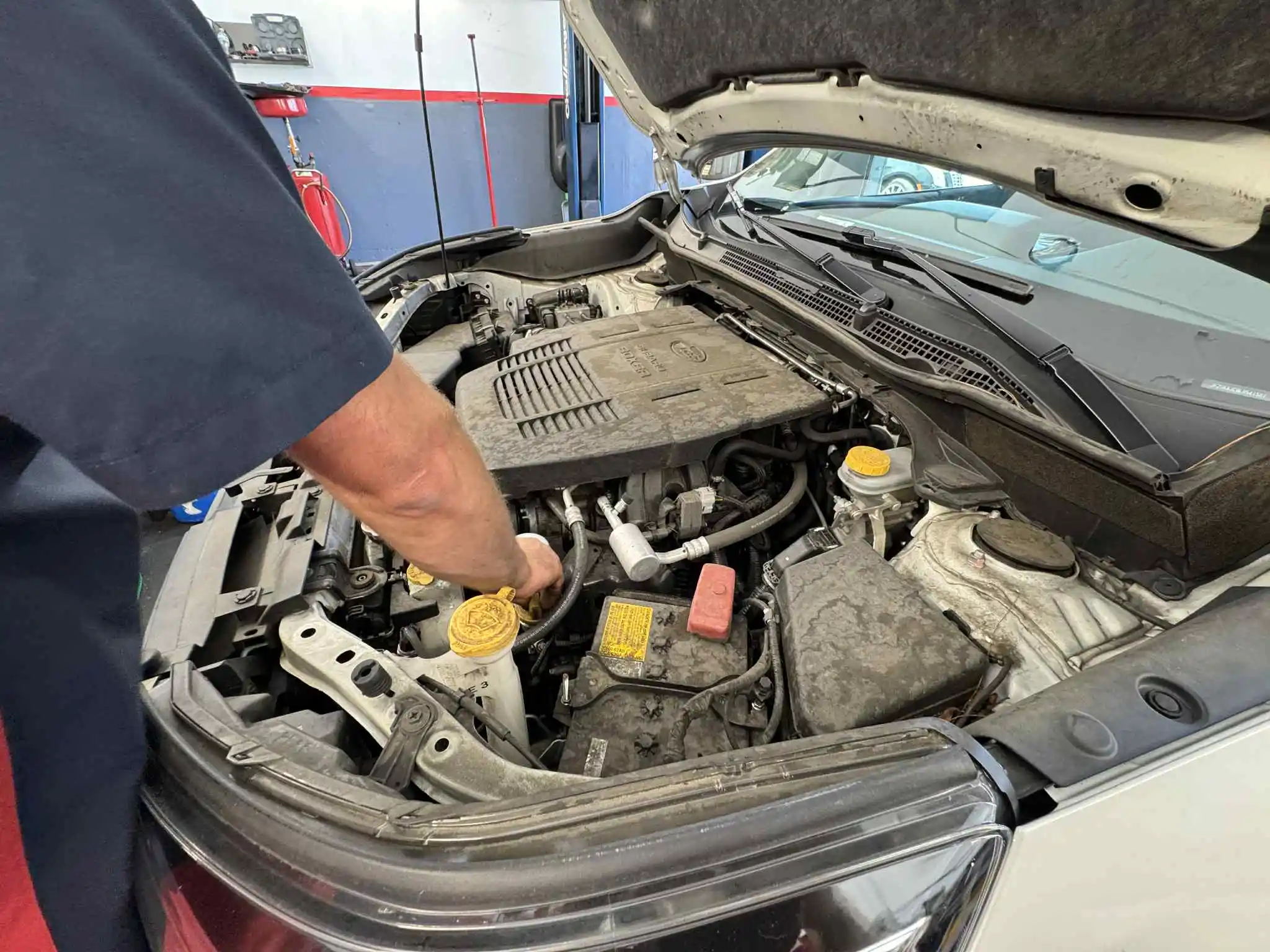

What Professional Brake Inspection Includes

Comprehensive evaluation identifies all brake system issues.

Visual Inspection: Technicians examine all visible brake components for wear, damage, and proper condition.

Measurement: Precise measurement of brake pad thickness and rotor dimensions determines remaining service life.

Caliper Evaluation: Testing caliper operation ensures proper function and identifies sticking or leaking components.

Hardware Assessment: Checking all clips, shims, and hardware components ensures complete, proper installation.

Brake Fluid Testing: Evaluating brake fluid condition identifies contamination or moisture that compromises brake performance.

Test Drive: Road testing allows technicians to experience brake noise and performance issues firsthand.

Complete Brake Service

Professional service addresses all identified issues.

Brake Pad Replacement: Installing quality brake pads matched to your vehicle and driving needs.

Rotor Service: Resurfacing or replacing rotors as needed to ensure smooth, true surfaces.

Hardware Replacement: Installing complete hardware kits with all necessary clips, shims, and components.

Caliper Service: Cleaning, lubricating, and servicing calipers to ensure proper operation.

Brake Fluid Service: Flushing and replacing brake fluid when needed to maintain hydraulic system integrity.

Final Testing: Thorough testing ensures proper brake operation, quiet performance, and safe stopping.

Why Choose ASE-Certified Technicians

Professional certification ensures competent brake service.

Comprehensive Training: ASE certification requires extensive knowledge of brake systems, diagnostic procedures, and proper service techniques.

Ongoing Education: Maintaining certification requires continuing education to stay current with evolving brake technologies.

Proven Competence: ASE certification demonstrates verified knowledge and skills through rigorous testing.

Quality Standards: ASE-certified technicians follow industry best practices and manufacturer specifications.

Preventing Brake Noise Through Proper Maintenance

Proactive care keeps brakes quiet and reliable.

Regular Brake Inspections

Scheduled inspections catch problems early.

Inspection Frequency: Having brakes inspected at least annually or every 12,000 miles allows early detection of wear and developing problems.

Service Integration: Combining brake inspections with other maintenance services like oil changes ensures regular monitoring.

Early Detection: Identifying wear before it becomes severe prevents noise, maintains safety, and minimizes repair costs.

Proper Driving Habits

How you drive affects brake longevity and noise.

Gradual Braking: Smooth, gradual braking reduces brake wear and heat generation compared to frequent hard stops.

Engine Braking: Downshifting or using lower gears on hills reduces brake system workload.

Following Distance: Maintaining adequate following distance allows gradual braking rather than frequent hard stops.

Anticipation: Looking ahead and anticipating traffic changes allows smoother, gentler braking.

Quality Parts and Service

Using quality components and professional service prevents problems.

Quality Parts: Investing in quality brake components ensures quiet operation, better performance, and longer service life.

Professional Installation: Proper installation by trained technicians ensures all components function correctly.

Complete Service: Replacing all necessary components during brake service prevents premature failure and noise.

Documentation: Keeping service records helps track brake system maintenance and plan future service needs.

Why Choose Speedway Tire for Brake Service

Speedway Tire provides expert brake service for Echo Park and surrounding Los Angeles communities.

ASE-Certified Expertise

Our technicians bring verified knowledge and skills to every brake service.

Professional Certification: Our ASE-certified technicians have demonstrated comprehensive brake system knowledge through rigorous testing and ongoing education.

Diagnostic Excellence: We accurately identify brake noise causes and all related issues through systematic inspection and testing.

Proper Service Procedures: We follow manufacturer specifications and industry best practices for all brake service work.

Quality Workmanship: Our technicians take pride in delivering brake service that ensures safety, performance, and quiet operation.

Quality Parts and Materials

We use components that deliver reliable, quiet performance.

Quality Brake Components: We install brake pads, rotors, and hardware that meet or exceed original equipment specifications.

Proper Materials: We select brake components appropriate for your vehicle, driving conditions, and performance needs.

Complete Hardware: Every brake service includes all necessary clips, shims, and hardware components for proper installation.

Warranty Coverage: Quality parts come with warranties that protect your investment.

Comprehensive Brake Service

We address all aspects of brake system condition.

Complete Inspection: We evaluate all brake components, not just obvious wear items, to identify all service needs.

Thorough Service: Our brake service addresses pads, rotors, hardware, calipers, and brake fluid as needed.

Proper Break-In: We provide guidance on proper brake break-in procedures to ensure optimal performance and longevity.

Final Testing: We thoroughly test brake operation after service to ensure proper function and quiet operation.

Convenient Echo Park Location

We serve Echo Park, Silver Lake, Los Feliz, Downtown LA, and surrounding neighborhoods.

Easy Access: Our location at 1165 West Sunset Blvd in Los Angeles provides convenient access for Echo Park residents and surrounding communities.

Neighborhood Service: We understand local driving conditions and how they affect brake systems.

Established Reputation: We've built our reputation on honest service, quality work, and fair treatment of every customer.

Customer Focus: We take time to explain brake system condition, service recommendations, and answer all your questions.

Take Action: Address Brake Squeaking Today

Don't ignore brake squeaking or other brake noises. While some brake noise stems from harmless causes like brake dust or moisture, other squeaking indicates serious problems that compromise safety and lead to expensive repairs if neglected.

Understanding brake noise causes helps you recognize when squeaking requires immediate attention versus when it represents minor issues. However, professional inspection provides the only reliable way to accurately diagnose brake problems and ensure your safety.

Brake systems represent your vehicle's most critical safety feature. Properly functioning brakes protect you, your passengers, and everyone sharing Los Angeles roads. When your brakes communicate through squeaking, squealing, or other noises, they deserve prompt professional attention from ASE-certified technicians who understand brake systems and provide quality service.

Hearing brake squeaking or other unusual brake noises?

Call Speedway Tire today at (213) 250-4254

Visit us at 1165 West Sunset Blvd, Los Angeles for expert brake inspection and service. Our ASE-certified technicians will accurately diagnose brake noise causes, explain all findings, and provide quality service that ensures safe, quiet brake operation.

We serve Echo Park, Silver Lake, Los Feliz, Downtown LA, and surrounding Los Angeles communities with honest, professional brake service you can trust.

Don't wait until brake squeaking becomes grinding or brake failure. Schedule your brake inspection today and drive with confidence knowing your brakes are safe, reliable, and quiet.

About Speedway Tire

Speedway Tire provides comprehensive automotive repair and maintenance services for Echo Park and surrounding Los Angeles communities. Located at 1165 West Sunset Blvd in Los Angeles, we serve Echo Park, Silver Lake, Los Feliz, Downtown LA, and nearby neighborhoods with honest, professional service.

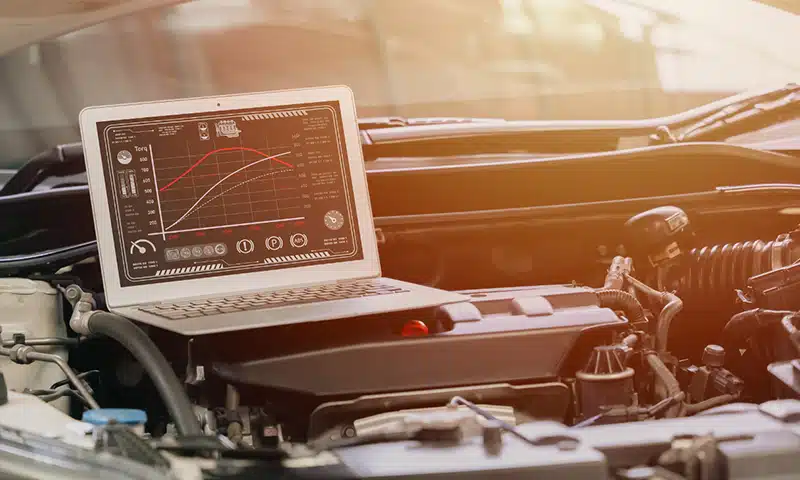

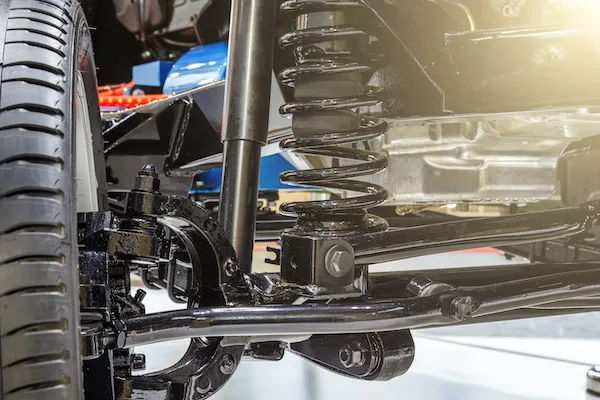

Our ASE-certified technicians bring verified expertise to every service, from routine maintenance to complex repairs. We specialize in brake service, tire sales and service, engine diagnostics, suspension work, and complete automotive care.

We believe in transparent communication, quality workmanship, and treating every customer fairly. When you choose Speedway Tire, you're choosing a neighborhood shop that values your trust and works hard to earn it with every service.

Contact Speedway Tire:

•Phone: (213) 250-4254

•Address: 1165 West Sunset Blvd, Los Angeles, CA

•Service Area: Echo Park, Silver Lake, Los Feliz, Downtown LA, and surrounding Los Angeles communities

Looking for an honest Auto Repair Shop in Los Angeles? Call Speedway Tire and Service Today

Whether you’re driving through LA traffic or cruising the freeways, your car deserves expert care. Located in Los Angeles, Speedway Tire and Service offers reliable oil changes, brake repairs, tire services, and more—all backed by experienced technicians and honest pricing.