Fleet Maintenance in LA: Keeping Your Business Moving

If you manage a fleet of vehicles in Los Angeles—whether it's a small delivery operation in Echo Park or a large commercial fleet serving all of Southern California—you know that every minute your vehicles are off the road, your business is losing money. In the competitive landscape of LA logistics, construction, and service industries, fleet vehicle maintenance isn't just about keeping trucks running; it's about protecting your bottom line, maintaining your reputation, and ensuring the safety of your drivers.

The reality is stark: according to industry research, vehicle downtime costs fleets an average of $448 to $760 per day, per vehicle. For a modest 10-vehicle fleet, a single week of unplanned downtime across your vehicles could cost upwards of $30,000 in lost revenue alone. That doesn't include the cascading costs of missed deliveries, damaged customer relationships, and emergency repairs.

So how do successful LA fleet managers keep their vehicles on the road and their businesses profitable? The answer lies in a strategic, proactive approach to maintenance.

The True Cost of Fleet Downtime

When a delivery van breaks down on the 101 or a service truck fails to start in a Downtown LA parking lot, the immediate problem is obvious: that vehicle can't generate revenue. But the downtime cost extends far beyond the lost trip.

Direct Financial Losses

Every hour a vehicle sits idle represents lost billable time. For delivery fleets, that's missed routes. For service companies, it's appointments that must be rescheduled. For construction operations, it's delays that can trigger contract penalties. These direct losses add up quickly, especially in a high-cost market like Los Angeles where margins are already tight.

Customer Satisfaction and Reputation

In today's world of instant communication and online reviews, a single missed delivery or late service call can damage your reputation. Customers expect reliability, and when your fleet can't deliver, they'll find a competitor who can. Research shows that 88% of consumers trust peer recommendations above all other marketing—meaning one unhappy customer can cost you many more.

Driver Morale and Retention

Your drivers are your most valuable asset, and they know when equipment isn't being properly maintained. Unreliable vehicles don't just frustrate drivers; they can put them in dangerous situations and reduce their earning potential. In a tight labor market, drivers have options. Companies that don't invest in proper fleet vehicle maintenance find themselves constantly recruiting and training new drivers—an expensive and disruptive cycle.

Operational Chaos

When one vehicle goes down unexpectedly, the ripple effects touch every department. Dispatchers scramble to reassign loads. Maintenance teams drop scheduled work to handle emergencies. Other drivers must alter their routes and schedules. What should be a smooth operation becomes a daily firefight.

The Preventive Maintenance Advantage

The good news? Most of these problems are preventable. A well-designed preventive maintenance schedule transforms fleet management from reactive chaos to proactive control.

What is Preventive Maintenance?

Preventive maintenance means servicing vehicles at regular, planned intervals based on time, mileage, or usage—before problems occur. Instead of waiting for a brake failure, you replace brake pads when they reach a certain thickness. Instead of dealing with a blown tire on the freeway, you rotate and inspect tires every 5,000 miles.

This approach offers multiple benefits:

Reduced Unplanned Downtime: By catching issues early during scheduled service, you avoid catastrophic failures that leave vehicles stranded. Scheduled maintenance happens during off-peak hours or slow periods, minimizing operational impact.

Lower Repair Costs: A $50 oil change prevents a $5,000 engine replacement. A $200 brake service prevents a $2,000 rotor and caliper overhaul. Preventive maintenance is always cheaper than emergency repairs.

Extended Vehicle Lifespan: Well-maintained vehicles last longer and retain higher resale value. This directly improves your fleet's return on investment.

Improved Safety: Regular inspections and maintenance reduce the risk of equipment failure that could cause accidents, protecting your drivers and the public.

Better Fuel Economy: Properly maintained vehicles with correct tire pressure, clean air filters, and tuned engines consume less fuel—a significant savings when you're running multiple vehicles in LA traffic.

Building Your Preventive Maintenance Schedule

An effective preventive maintenance program requires structure. Here's how to build one:

1. Know Your Vehicles: Different vehicle types and uses require different maintenance schedules. A delivery van making 50 stops a day in stop-and-go traffic needs more frequent service than a highway truck. Consult manufacturer recommendations and adjust based on your specific operating conditions.

2. Track Everything: Implement a system to track mileage, hours, and service history for every vehicle. Modern fleet management software can automate this, sending alerts when service is due.

3. Create Service Tiers: Establish different service levels:

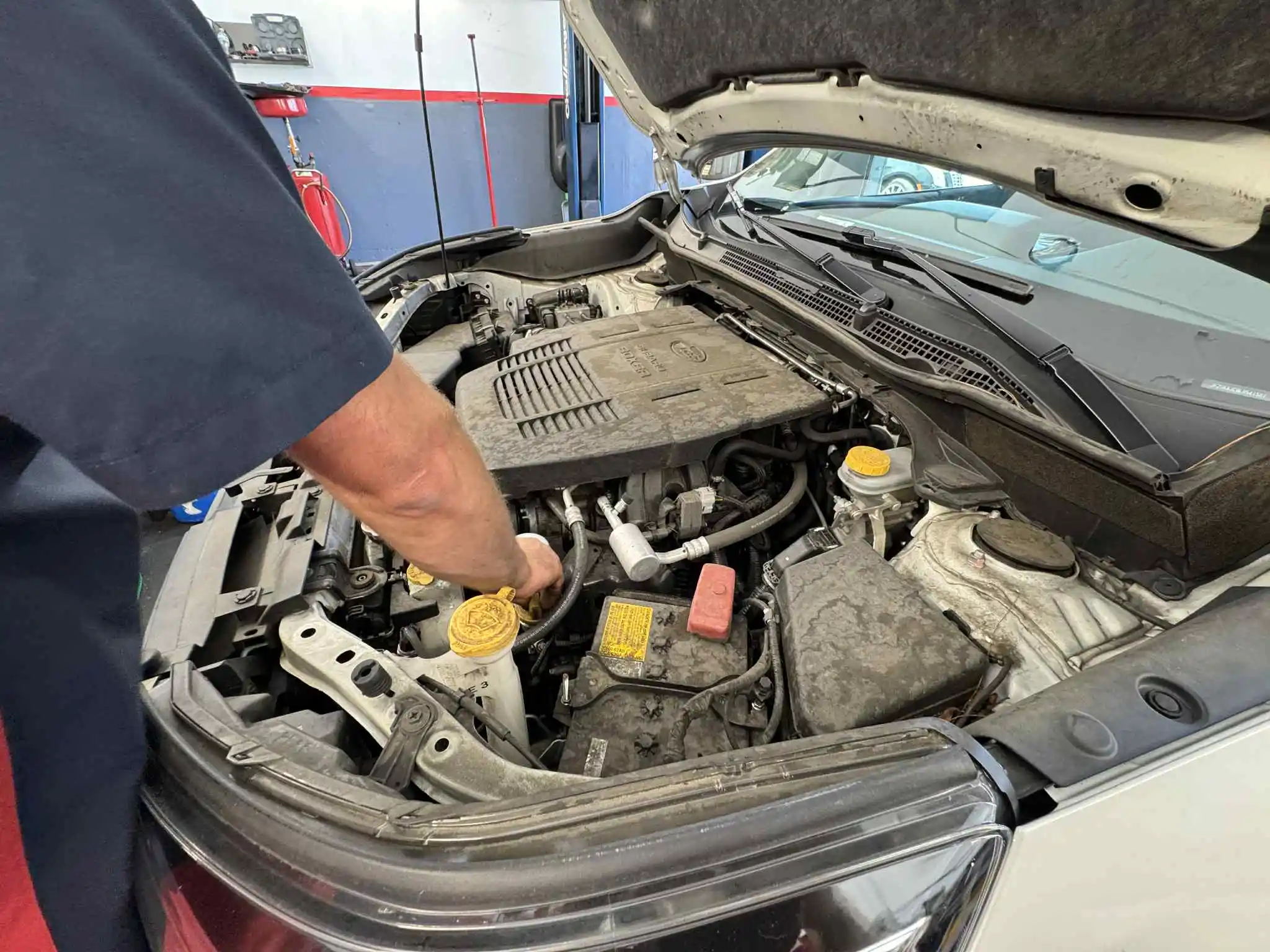

•A-Level Service (every 3,000-5,000 miles): Oil change, fluid checks, tire rotation, basic inspection

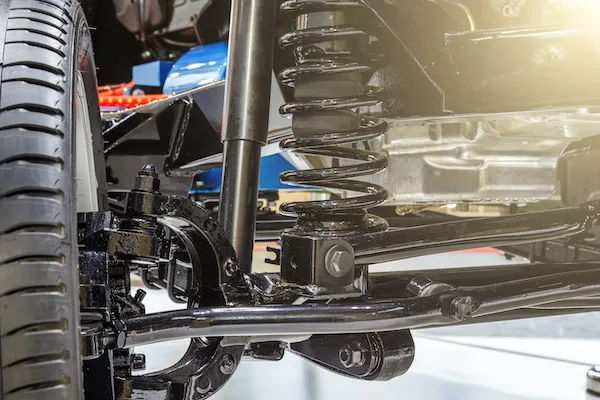

•B-Level Service (every 15,000-20,000 miles): All A-level items plus brake inspection, suspension check, battery test

•C-Level Service (annually or 30,000+ miles): Comprehensive inspection including transmission service, coolant flush, timing belt evaluation

4. Schedule Strategically: Plan maintenance during your slowest operational periods. For many LA businesses, this might be weekends or specific seasonal lulls. Having a relationship with a service provider who offers flexible hours can be invaluable.

5. Don't Skip Services: When business is busy, it's tempting to push maintenance back "just one more week." Resist this urge. Skipping scheduled maintenance is how small problems become big, expensive failures.

Expert Insight: According to the National Association of Fleet Administrators (NAFA), fleets that implement comprehensive preventive maintenance programs see up to 30% reduction in overall maintenance costs and 25% improvement in vehicle uptime compared to reactive maintenance approaches.

Strategic Partnerships: Why Your Service Provider Matters

For LA fleet managers, choosing the right maintenance partner is critical. You need a provider who understands the unique demands of fleet vehicle maintenance—someone who can handle multiple vehicles efficiently, source parts quickly, and work within your operational constraints.

What to Look for in a Fleet Service Provider

Commercial Vehicle Expertise: Not all auto shops are equipped to handle fleet needs. Look for providers with experience in commercial vehicles, proper lift capacity, and technicians certified in the types of vehicles you operate.

Bulk Tire Pricing and Services: Tires are one of your largest ongoing expenses. A provider offering bulk tire pricing can significantly reduce costs. For a 10-vehicle fleet replacing tires twice a year, bulk pricing can save thousands of dollars annually. Additionally, look for services like on-site tire installation or emergency tire service to minimize downtime.

Fast Turnaround: Time is money. Your service provider should be able to handle routine maintenance quickly and efficiently. Ask about their capacity to service multiple vehicles simultaneously and their typical turnaround times.

Transparent Communication: You need real-time updates on vehicle status, clear explanations of recommended repairs, and accurate cost estimates. The best fleet service providers assign you a dedicated account manager who understands your business and can prioritize accordingly.

Flexible Scheduling: Your business doesn't operate 9-to-5, and neither should your maintenance provider. Look for extended hours, weekend availability, and the ability to accommodate emergency situations.

At Speedway Tire & Service, we understand these needs. Our team has extensive experience with fleet operations throughout Los Angeles, and we offer specialized services designed to keep your business moving, including comprehensive vehicle maintenance programs tailored to commercial fleets.

The ROI of Proactive Fleet Maintenance

Let's look at a real-world example. Consider a 10-vehicle delivery fleet operating in LA:

Reactive Maintenance Scenario:

•Average unplanned downtime: 5 days per vehicle per year

•Downtime cost: $600/day × 5 days × 10 vehicles = $30,000

•Emergency repair premium: 20% higher than scheduled maintenance

•Total annual maintenance cost: $45,000

•Lost customer relationships: 3 major accounts

•Total annual cost: $75,000+ plus lost business

Preventive Maintenance Scenario:

•Planned maintenance schedule with minimal operational disruption

•Unplanned downtime: 1 day per vehicle per year

•Downtime cost: $600/day × 1 day × 10 vehicles = $6,000

•Scheduled maintenance cost: $35,000

•Customer retention: 100%

•Total annual cost: $41,000

Net Savings: $34,000+ annually, plus preserved customer relationships and driver satisfaction.

The numbers speak for themselves. Preventive maintenance isn't an expense—it's an investment that pays immediate and ongoing returns.

Tire Management: A Critical Fleet Component

For fleet vehicles, tires represent both a significant cost center and a critical safety component. Proper tire management is essential to any fleet vehicle maintenance strategy.

The Fleet Tire Challenge

Fleet vehicles are hard on tires. Constant loading and unloading, frequent stops, curb strikes, and LA's pothole-riddled streets all accelerate tire wear. Add in the heat of Southern California summers, and tire life can be significantly shortened.

Best Practices for Fleet Tire Management

Regular Inspections: Check tire pressure weekly and conduct visual inspections for damage, uneven wear, or embedded debris. Under-inflated tires reduce fuel economy and increase the risk of blowouts.

Rotation Schedule: Rotate tires every 5,000-7,000 miles to ensure even wear and maximize tire life. This is especially important for vehicles with uneven weight distribution.

Alignment Checks: Misalignment causes rapid, uneven tire wear and poor handling. Have alignment checked whenever you notice pulling, after hitting a significant pothole, or annually as part of preventive maintenance.

Bulk Purchasing: Negotiate bulk tire pricing with your service provider. Buying tires for your entire fleet at once can yield significant discounts—often 15-25% off retail pricing.

Quality Matters: While it's tempting to buy the cheapest tires, quality tires last longer and perform better. For fleet applications, look for tires rated for commercial use with good tread life warranties.

Our tire services at Speedway include fleet-specific solutions, from bulk purchasing to mobile tire service that brings our technicians to your location.

Technology and Fleet Maintenance

Modern fleet management increasingly relies on technology to optimize maintenance schedules and reduce costs.

Telematics and Diagnostics

Many newer commercial vehicles come equipped with telematics systems that provide real-time data on vehicle health, location, and performance. These systems can:

•Alert you to maintenance needs before they become critical

•Track fuel consumption and identify inefficient vehicles or drivers

•Monitor engine diagnostics and predict failures

•Provide proof of maintenance for compliance purposes

Fleet Management Software

Dedicated fleet management software helps you:

•Schedule and track maintenance across your entire fleet

•Manage parts inventory

•Analyze maintenance costs and identify problem vehicles

•Generate reports for budgeting and planning

While technology is powerful, it's not a replacement for hands-on maintenance by skilled technicians. Think of it as a tool that helps you make better decisions about when and how to service your vehicles.

Seasonal Considerations for LA Fleets

While Los Angeles doesn't experience the extreme seasonal changes of other regions, there are still important seasonal maintenance considerations.

Summer Preparation

LA summers are brutal on vehicles. High temperatures stress cooling systems, accelerate battery failure, and increase tire pressure. Before summer hits:

•Test and service air conditioning systems

•Check coolant levels and condition

•Inspect hoses and belts for cracking

•Test batteries (heat kills batteries faster than cold)

•Adjust tire pressure for temperature increases

Winter Readiness

LA winters bring rain and occasional cold snaps. Prepare your fleet by:

•Replacing worn wiper blades

•Checking tire tread depth (critical for wet traction)

•Testing lights and visibility systems

•Inspecting brakes (wet conditions demand reliable stopping power)

These seasonal checks can be incorporated into your regular preventive maintenance schedule to ensure your fleet is ready for whatever LA weather brings.

Building a Culture of Maintenance

The best fleet maintenance programs involve everyone, not just the maintenance team.

Driver Responsibility

Drivers are your first line of defense. They should be trained to:

•Conduct pre-trip inspections

•Report unusual noises, vibrations, or performance issues immediately

•Check tire pressure and fluid levels regularly

•Keep vehicles clean (dirt and grime can hide problems)

Create a culture where reporting problems is encouraged and rewarded, not punished. Drivers who feel responsible for their vehicles take better care of them.

Management Commitment

Fleet maintenance requires investment—in time, money, and attention. Management must:

•Budget adequately for preventive maintenance

•Resist the temptation to skip services during busy periods

•Recognize and reward drivers who maintain vehicles well

•Track and analyze maintenance data to identify trends

Getting Started with Speedway Tire & Service

If you're ready to transform your fleet maintenance from reactive to proactive, Speedway Tire & Service is here to help. We offer:

•Comprehensive Fleet Services: From routine oil changes to major repairs, we handle all your fleet maintenance needs

•Bulk Tire Pricing: Significant savings on quality tires for your entire fleet

•Flexible Scheduling: We work around your operational schedule to minimize downtime

•Experienced Technicians: Our team has extensive experience with commercial vehicles of all types

•Transparent Pricing: Clear, upfront estimates with no surprises

•Account Management: Dedicated support to help you manage your fleet maintenance program

Don't let unexpected breakdowns cost you money and customers. Contact us today to discuss your fleet needs and learn how our preventive maintenance programs can keep your business moving.

Whether you're running a small fleet in Silver Lake or managing dozens of vehicles across LA, we have the expertise and capacity to be your trusted maintenance partner. Let us help you reduce costs, improve uptime, and focus on what you do best—running your business.

Looking for an honest Auto Repair Shop in Los Angeles? Call Speedway Tire and Service Today

Whether you’re driving through LA traffic or cruising the freeways, your car deserves expert care. Located in Los Angeles, Speedway Tire and Service offers reliable oil changes, brake repairs, tire services, and more—all backed by experienced technicians and honest pricing.